Description

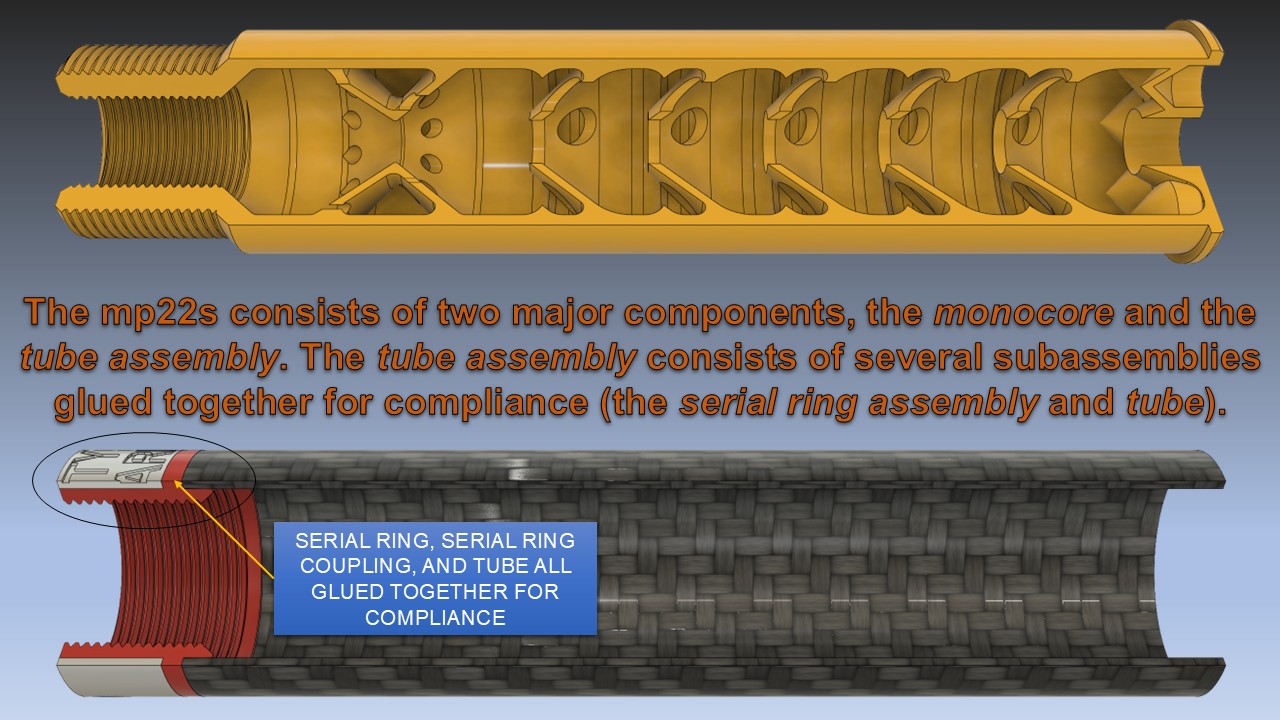

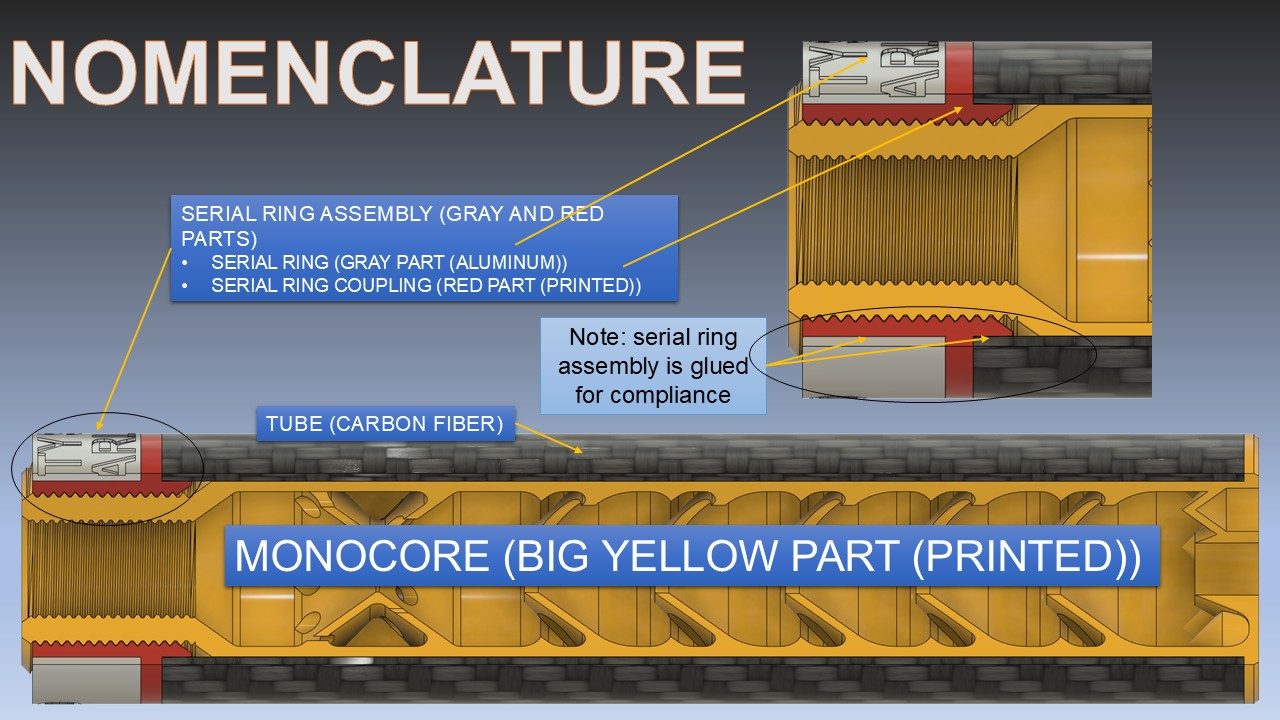

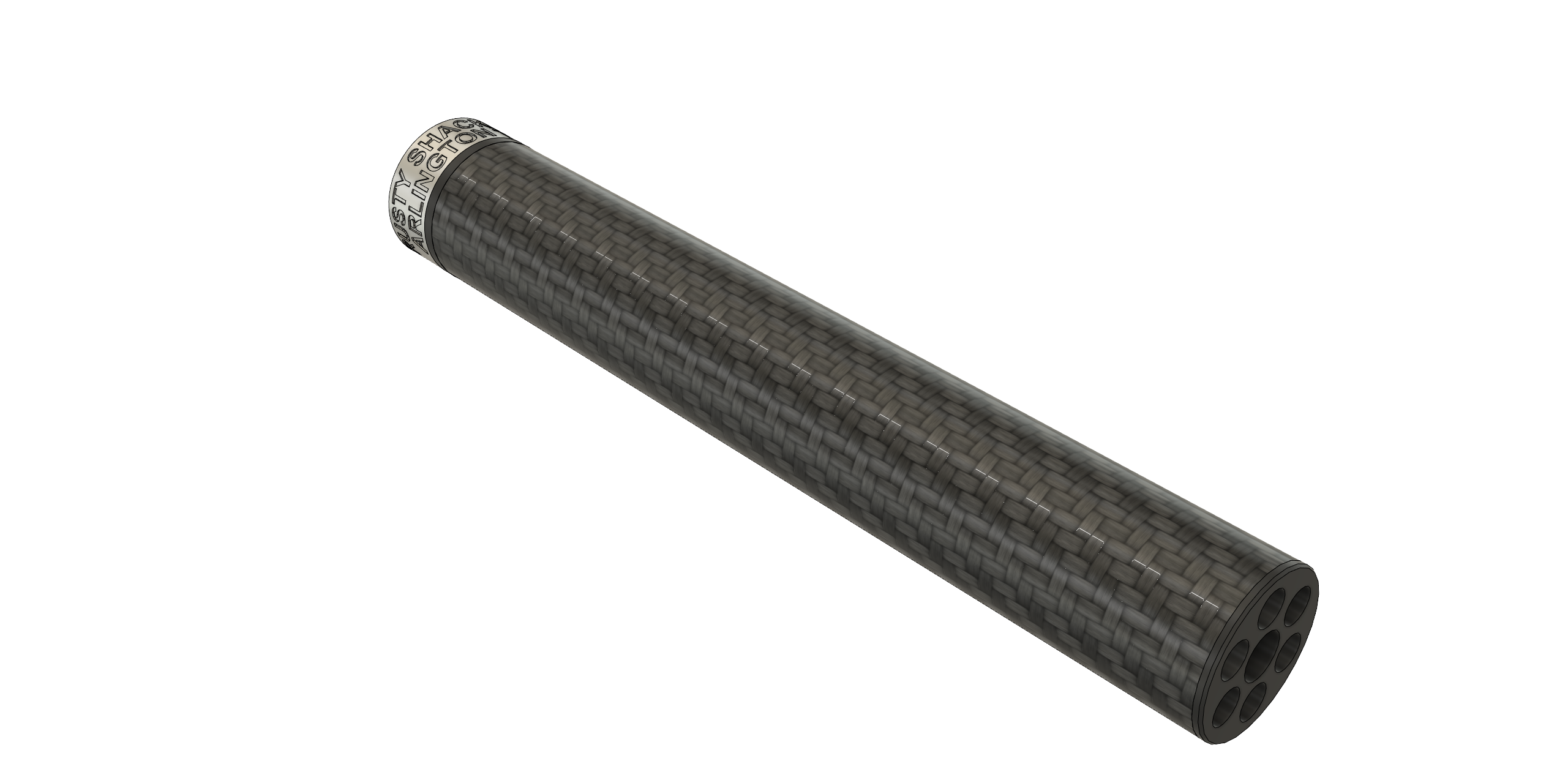

The mp22s is a fully serviceable 22lr silencer that’s optimized for long range plinking, featuring 3d printed monocores that can be swapped in ten seconds.* V1s feature an aluminum serial ring, while the updated V2s do not (you simply serialize the carbon fiber tubes directly). They cost about five dollars each to make (about four dollars in carbon fiber tubing and about fifty cents in filament), and the fabrication process is extremely easy and foolproof, and doesn’t require any special tools, supplies, or skills.

This is a fully-featured data package for the casual DIYer that includes:

- STLs for all parts

- 3D printable tools for measuring, cutting, and squaring the tubing to a high level of precision

- Printable endcap wrench

- Hand drawn supports (only applicable to V1s, V2s have no supports anywhere) integrated into model, precluding need for messy autogenerated supports in slicer

- A 30+ page guidebook with 35+ photos and diagrams that includes:

- Complete build instructions

- Complete materials list

- Comprehensive slicer settings and print orientations

- Detailed information on filament selection

Why 3d printed? Most obviously, the 3d printed monocores are cheap to print, so once they shoot out or fill up with fouling, you can simply discard them, negating the need for messy cleaning. The cores are completely sealed, so all the fouling is contained, meaning you never have to handle any fouled parts, and there’s no carbon lock, meaning you’ll never have to soak them or muscle them apart like you do with metal silencers that carbon lock and can be frustrating to disassemble for servicing.

The biggest advantage is that we can risk a much tighter bore than we ever would with an expensive metal core, leading to a much more accurate, much quieter silencer. This is especially important for this style of baffle because they don’t have clips, leading to greater accuracy (users are reporting no discernable POI shift). But unclipped baffles, while great for precision, come at the expense of reduced suppression. However, due to its tighter bore, the mp22s performs on par with traditional single clipped baffles, which always come with a large POI shift and increased group size due to the asymmetric turbulence they generate inside the can (which is excellent for suppression, but at the expense of accuracy). Long story short, the mp22s is as quiet as a traditional clipped baffle silencer, but without the associated loss of precision.

The weight, or lack thereof, is also very important for precision. Any weight hung on the end of a barrel will change the barrel’s harmonics (point in the barrel’s whip arc at which the bullet exits), leading to a POI shift and increased group size. The smaller the weight, the less impact it has on harmonics. I doubt there’s a lighter silencer on the market, as these are 45 grams (1.5oz) for the full sized V1 (which is absolutely nuts for a 6″ can).

I also believe there’s some advantage to the porosity, texture, and soft, flexible nature of the printed baffles for sound dampening. These have a very pleasant tone in addition to being super quiet, and have absolutely no discernable first round pop. You generally have to use ablative with a metal silencer to get this kind of tone and this level of reduced first round pop.

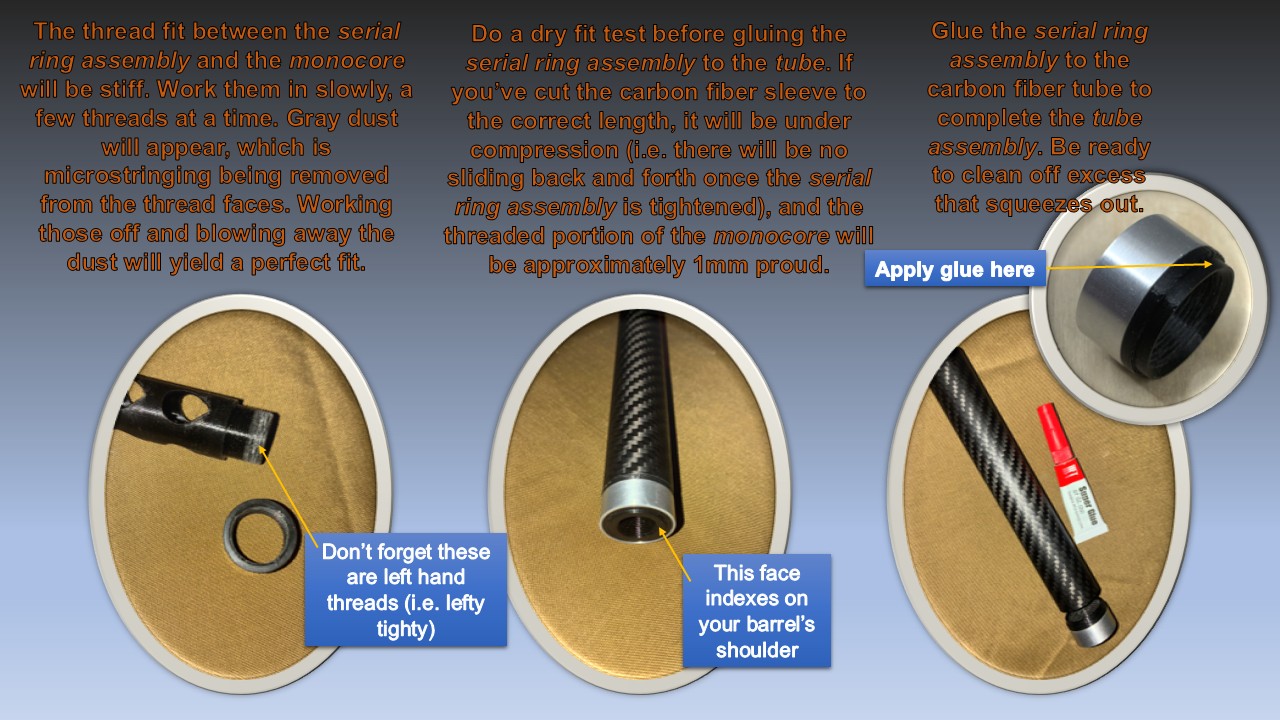

The outer body is joined to the monocore by left hand threads, which compress the muzzle threads in the opposite direction, creating an equal and opposite force that prevents the fine 3D printed muzzle threads from stretching and jumping when you snug the silencer onto your barrel. This precludes the need for metal thread adapters, allowing for direct thread, thereby avoiding the stacked tolerances associated with thread adapters. The muzzle threads melting has not been identified as a failure mode on any barrel length or firing schedule, so I’ve come to the conclusion that thread adapters are completely unnecessary anyways.

Please note that the K can is NOT for pistols. In fact, I wouldn’t recommend it for barrels under 16″ (not because it’s less durable than the full size version, but simply because it won’t sound very good). The K can is specifically intended for longer barrels that don’t require as much suppression to sound stellar. The longer the silencer, the heavier it is, the more it impacts harmonics, and the more baffles the more opportunity there is for POI shifts and loss of precision. Thus, it’s better for precision to use the least amount of silencer possible to achieve the desired result. All that said, if the K can sounds good on your SBR, and you’re happy with that level of performance, and willing to trade a few dBs for a hypothetical gain in precision, even the K can still sounds pretty good. I can definitely tell a difference between the full size and K versions on 10-12″ barrels, but I can’t really detect a difference on 16-20″ barrels. But with tax stamps now free, you might as well try both of them, right?

So which version should you make? The V2 is actually the version I WANTED to make from the get go; it simply wasn’t practical with stamps costing $200 and wait times in the months or even years at that time. Nobody, including me, was going to burn a stamp on a serialized part that wasn’t forever. The V1 was a compromise on my part from day one. So in a way, the V2 is actually more like a V0. It’s obviously a little bit cheaper and easier to make because you don’t have to fabricate the serial ring, but it’s also just a more elegant design. Irrespective of regulatory considerations, the V2 is the clear winner. That said, the V1 future proofs your silencers against possible tax increases (or worse), which is why I’m continuing to offer it, and it does look pretty, especially if you anodize the aluminum. That said, even the V2 will likely last you a lifetime, though there is obviously a much higher risk that the serialized part, being carbon fiber composite, would become irreversibly damaged, precluding future repairs. There’s also an increased chance of losing the carbon fiber tube, as it will launch downrange if the core fails, potentially getting lost in the brush or being otherwise irretrievable. Not a biggie if all you lose is a few bucks of tubing and the ten minutes it takes to file another Form 1, but a real bummer if the regulatory situation changes in the meantime. In other words, if you forego the serial ring (and serialize the carbon fiber tube directly), there is always that chance that the tube gets lost or damaged, which would be a bummer if the tax or wait times go back up, or…if they were to close the registry to silencers altogether. For what it’s worth, the serial ring IS extremely effective for its purpose, as it’s both durable and basically impossible to lose in the event of a core failure. I actually did test that by destroying a can by way of P90 (the printed core and carbon fiber tube basically dematerialized), and the serial ring did remain firmly attached to the muzzle, undamaged, allowing for SOT repair and recore. You can take it even further by making the ring out of titanium if you really want to be sure.

Now for the elephant in the room, durability: 22lr ONLY, and not recommended for barrels under 10″ or full auto simulation devices like the binary or forced reset type triggers. While obviously not as durable as a metal can, the mp22s is durable enough for its intended purpose (longer range, more precision oriented use). I’ve fired several hundred rounds in a single session on a 12″ barreled semi auto 10/22 with Federal bulk pack ammo, as well as done several back to back mag dumps (four 10 round mags), and the cores have survived intact. The cores will survive the pressure down to about a 5″ barrel, but the heat builds up very quickly, meaning you only get a few shots before the baffles melt. Anything under 5″ will overpressure the baffles and shatter them on the first shot.

On a final note, I truly believe that the mp22s will continue to get better and better as more durable, heat resistant filaments make their way into the consumer space. We’ve come a long ways, and consumer grade printers and materials are starting to really catch up. It’s even hypothetically possible that SLS or even DMLS might be coming to the home printer market at some point in the near future. So who knows…an mp22s without barrel length or rate of fire restrictions might be in the cards at some point in the future.

*This design utilizes a perishable monocore that is akin to wipes in the sense that the monocore is, despite being perishable, considered a silencer part under US law, and therefore you cannot have spares. While silencers can be “recored” as long as the serialized part is intact, you cannot possess extra cores to have as backups, for the exact same reason you can’t have extra wipes. The ATF also holds that replacement of silencer parts must be performed by a licensed SOT. I recommend finding a hobbyist SOT in your area to help you with the maintenance of your mp22s. The easiest workaround is to simply register and make several of these, and keep a spare in your range bag (the minimum order of carbon fiber tubing is generally enough to make 5-10 bodies).

Reviews

There are no reviews yet.